Business Overview

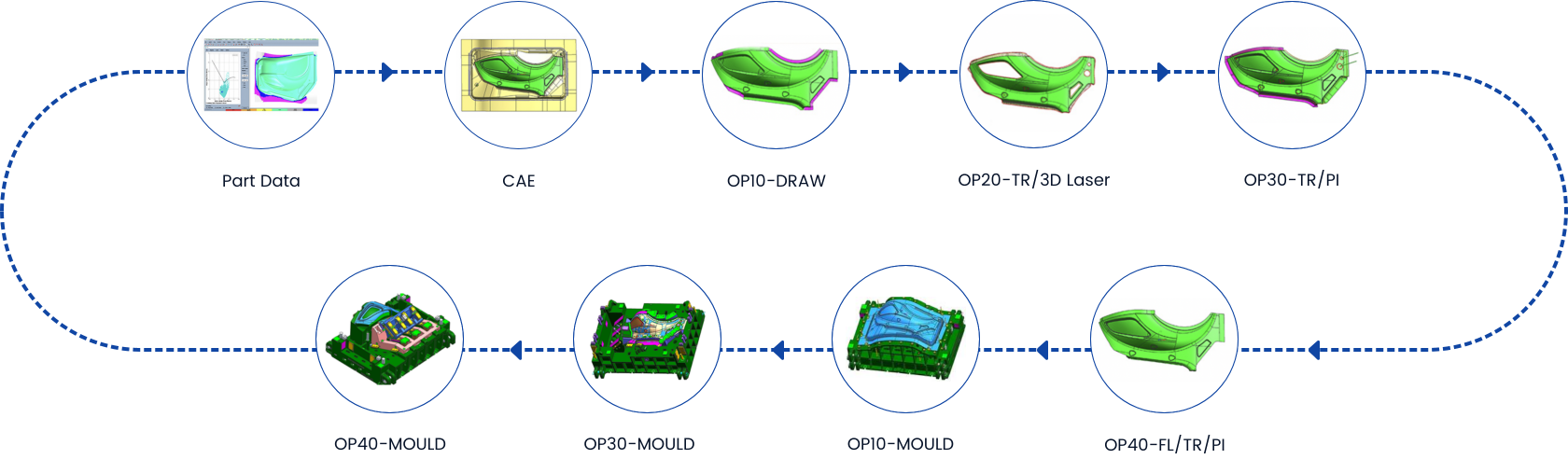

Based on customer demands, we can align closely with the customer’s product development at any stage. This enables efficient completion of tasks such as reverse modeling, SE synchronous engineering, CAE simulation analysis, and structural design. We undertake various automotive body stamping moulds, chassis stamping moulds, rolling equipment, body engineering samples, and spot welding products. We offer customers an overall solution involving product design, mould development, and process support, with a focus on short lead times and cost efficiency.

English

English French

French Spanish

Spanish Russian

Russian